Due to the huge number of tractor models and implements such as the Rapid Spray 'SprayLink' 3PL sprayer, there is no such thing as a one-size-fits-all PTO shaft.

Tractor models vary in the dimensions between the bottom link arms and the PTO shaft output and so do implements resulting in a need to adjust the length of your PTO shaft to ensure safe operation prior to the first use.

**WARNING: PTO shafts are extremely dangerous and can cause grievous bodily harm or death if incorrectly used. Follow all manufacturer instructions and Safe work methods when using PTO driven machinery.

Skip to the following steps:

1. Measuring Your Shaft for Correct Length

2. Cutting & Cleaning Your Shaft

3. Cutting the Safety Guard to Length

4. Fitting & Testing for Correct Fit

Measuring Your Shaft for Correct Length

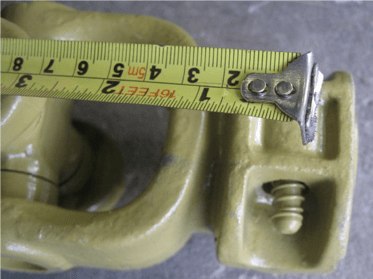

1. Hitch your implement to your tractor using the 3PL arms and raise it to the height where the PTO output shaft on the tractor and the implement align horizontally with each other.2. At this point they will be closer together than when the implement is resting on the ground;Measure from the groove which runs around the shaft on the tractor to the same position on the implement and take note of this measurement;

3. Take the new PTO shaft and remove the safety guard from either end;

4. Push the two halves together so the shaft is at its shortest length and measure from one locking pin to the other, taking note of this measurement;

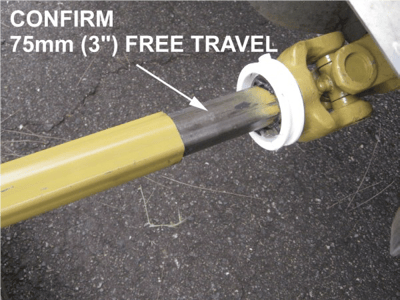

5. The required shaft length is the first measurement (from groove to groove) minus a minimum of 76mm (3") to allow for disconnection from the tractor. If the shaft is already shorter than this, ensure that a minimum of 50% of total shaft length overlaps when in operation.

CUTTING & CLEANING YOUR SHAFT

1. Amount to cut off shaft:

Length of the new shaft (from step 4) - the groove to groove measurement (from step 2) + 76mm = Cut-Off Total

Then, take the cut-off total and cut half of this measurement off each end of the shaft.

For example:

| New Shaft Measurement (step 4) | 1194 |

| less Groove to Groove Measurement (step 2) | - 890 |

304 |

|

| plus 76mm for Clearance | + 76 |

Total Amount to Cut Off each end of shaft |

380 |

| Finished measurement of shaft should be | 814 |

2. Cut half of the cut-off amount off both ends of the shaft using a hacksaw or metal saw. Remove burrs using a file from the inside and outside of the cut ends. Grease both ends of the shaft and slide them together to the shortest length;

It is now necessary to cut the safety guard tube to length to match the now shortened shaft. Follow the steps below.

Cutting your Safety Guard to Length

1. Cut the same amount off both safety tubes as you did in step 7 to the shaft ends using a hacksaw. Deburr ends and remove any plastic shavings;

2. Re-install shaft safety guards to shaft ensuring they have locked into place.

Fitting & Testing for Correct Fit

**Do not operate the tractor PTO until correct fitting has been checked. **

3. Install PTO shaft onto tractor and implement while shaft is horizontal and at its shortest length. If you cannot fit the shaft at this point as it is too long, it will need to be shortened further;

4. Without running the PTO, lower the implement to the ground and check the angle of the shaft and universal joints. This angle should not exceed 25 degrees at rest;

5. Raise the implement to the maximum operating height and check the angle of the shaft and universal joints. This angle should not exceed 17 degrees for continuous operations;

6. Lastly, check the overlap of the shaft ends exceeds 50% of the total length of the shaft operation to prevent premature failure of the shaft.

Great work! You've now correctly sized your PTO shaft to your implement. If you were unable to complete any of the above steps or measurements, do not attempt to operate your implement until you have consulted with the supplier. Some implements may require modification in order to correctly fit compact tractors or front end PTO linkages. Spray pumps can be easily relocated for safer operation if needed by moving them further back on the mounting plate o in some instances, raising the height of the pump on a additional mounting plate.

If you liked this article or have a question, feel free to leave a comment below to let us know how we’re doing and we will get back to you ASAP!